Submit a request

Our manager will contact you

Renovation and upgrading of the existing power supply system of the Business Center

Feb 9, 2022

This project was implemented in three stages. At the first stage, we conducted an inspection of the existing power supply system. At the second stage, we selected an optimal solution to address the main issues identified during the inspection. And we also made a design and coordinated the project and estimates with the customer. At the third stage, we implemented the project. Please see a step-by-step implementation of the project below.

The results of the inspection of the power supply system of the BC building

Necessary for the life support of the building. Such as:

Photo 1. The main distribution board (MDB) of the building

Tenants’ distribution board (DB 1) (Photo 2):

Photo 2. Tenants’ distribution board (DB 1)

Tenants’ distribution boards (DB 2, DB 3) (Photo 3):

Photo 3. Tenants’ distribution boards (DB 2, DB 3)

Automatic transfer switch (ATS) board (Photo 4):

Photo 4. Automatic transfer switch (ATS) board

Backup diesel generator set (DGS) (Photo 5):

Photo 5. Backup diesel generator set (DGS)

General comments made during the inspection:

Solution

We have selected the optimal solution to address the identified issues, with due regard to the financial capacities of the customer:

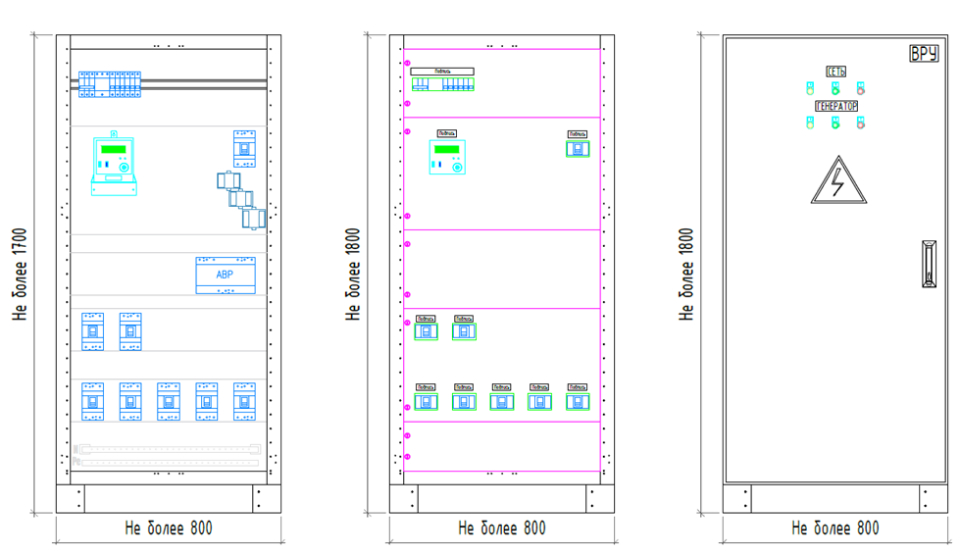

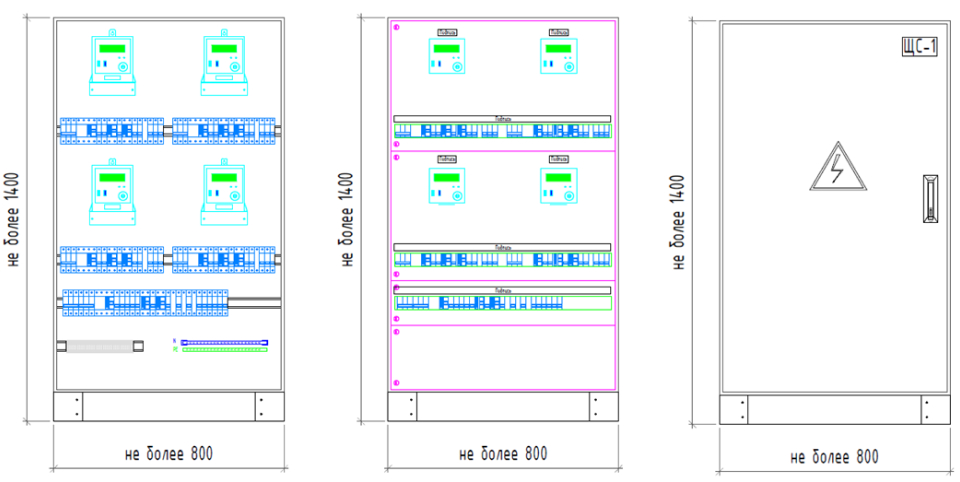

MDB drawing

MDB drawing

For AQTech website

Submit a request

Our manager will contact you